| dc.contributor.author | Nelabhotla, Anirudh Bhanu Teja | |

| dc.date.accessioned | 2020-03-23T19:01:55Z | |

| dc.date.available | 2020-03-23T19:01:55Z | |

| dc.date.issued | 2020-03-27 | |

| dc.identifier.isbn | 978-82-7206-547-7 | |

| dc.identifier.issn | 2535-5252 | |

| dc.identifier.uri | https://hdl.handle.net/11250/2648225 | |

| dc.description.abstract | Power to Gas (PtG) is being viewed as systemic innovation in terms of integrating renewable electricity systems and wastewater treatment systems to provide renewable transport fuel. The highly varied nature of the sun and wind does usually produce either less or more electricity than the required amount during certain period of the day or a year. The PtG technologies can be integrated with the renewable electricity systems that are able to utilize the excess electricity to produce renewable transport fuel. This helps not only save the electricity produced but also integrate the transportation sector in the renewable energy ecosystem.

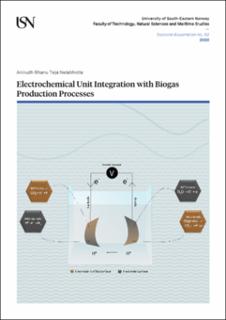

The current thesis addresses a specific use of PtG with the help of microbial electrosynthesis (MES) to upgrade biogas in food waste/wastewater treatment systems. The thesis starts with an extensive state-of-art review of all the existing reactor configurations especially single chambered systems, cathode materials that support biofilm growth, electron transfer mechanism and finally the integration of MES with anaerobic digestion (AD) systems. It also identifies research gaps in terms of lack of analysis and optimisation experiments in terms of pH and cathode potentials in single chamber continuous flow reactor configuration. A major research gap is identified in terms of direct interspecies electron transfer (DIET) and using anaerobic reject water as feed for biogas upgrading. This thesis attempts to address the gaps identified and contributes to the literature on MES integrated AD systems.

Simple cyclic voltammetry tests were first used on artificial wastewater to compare the different electrode materials and it was identified that carbon felt performs relatively similar to platinum-coated titanium as an anode. The experiments also provided approximate optimised values of pH and temperature for MES operation. Carbon felt was subjected to MES operation at -0.80 V for over 2 months in fed batch mode to grow biofilm. Two of the biocathodes were selected and different optimisation experiments were conducted at different operational conditions.

It was observed that the pH directly affects the heterotrophic methanogenesis and the electrochemical methane production indirectly through the availability of CO2/HCO3-. The reactor pH must be controlled below 8.0, which implied that the feed pH must be in the range of 7.0 to 7.2. The main reasons identified for the increase in pH is the consumption of protons and acetic acid through heterotrophic methane production with simultaneous conversion of CO2 to bicarbonate/metane. The optimised cathode potential for methane formation was identified to be around -0.65 V vs Standard Hydrogen Electrode (SHE) whereas for acetic acid formation to be above -0.80 V vs SHE.

In order to study the electron transfer mechanisms, electrochemical experiments at both the above-mentioned cathode potentials were compared with each other. Blank and control experiments were also conducted to compare the methane production and acetic acid consumption rates. The baseline MES operation (19.5 mmol/L(reactor)-d) showed 13 – 39% more methane than the control experiment (16.5 – 14.5 mmol/L(reactor)-d) in terms of methane production rates. It was demonstrated that the effluent pH could be lowered by feeding low concentrations of acetic acid. This also showed a simultaneous increase in current production and decrease in alkalinity concentrations, denoting biocathode adaptation to electrochemical conditions.

Further adapting the biocathode to feed with no supplemented acetic acid (reject water from sludge AD at Knarrdalstrand wastewater treatment plant, Porsgrunn) increased the methane production rate by 50% from 4.0 mmol/L(reactor)-d to approximately 6.0 mmol/L(reactor)-d. All the continuous flow experiments were conducted at 24-h HRT and reactor pH (measured in the effluent) through the different operating conditions was brought down to 8.2 from 8.7. HRTs lower than 24 h were analysed for lowering the pH below 8.0 and other observations were made regarding biogas production rates and methane concentrations. The 18-h HRT operation showed 12.2 and 7.4 mmol/L(feed)-d methane production yield respectively with approximately 90% methane concentration in the biogas. High COD removal of approximately 40.6 and 23.4% were observed in the 18-h HRT MES operations of feeds with and without supplemented acetic acid. Moreover, observations were made regarding electro-oxidation of COD at the anode. As the HRT is lowered to 12 hrs and below, the current production shows an increase with a corresponding decrease in alkalinity concentrations. This denoted enhanced electrochemical activity. However, when HRT was reduced below 6-hrs the amount COD removal decreased along with decrease in CO2 reduction rate resulting in higher CO2 biogas content.

A total of 4 mechanisms for methane production are observed in the thesis and are discussed as part of unpublished work. It is concluded that 45% of total methane produced in feeds that do not contain acetic acid is via the direct interspecies electron transfer mechanism (DIET) by converting bicarbonate to methane. Finally, the thesis concludes with a proposed scale-up of MES-AD integration at the Knarrdalstrand WWTP from where the feed was sourced during the course of thesis. It is estimated that an MES reactor sized approximately 82m3 preferably in multi-train tubular configuration. The extrapolated values show 4% increase in methane production only through reject water treatment and doesn’t include CO2 conversion. CO2 conversion to methane is expected to increase in plug flow configuration as the electrode surface area to reactor volume ratio increases. However, the final COD is estimated to decrease by 15-20 % by extrapolating results obtained in thesis. | en_US |

| dc.language.iso | eng | en_US |

| dc.publisher | University of South-Eastern Norway | en_US |

| dc.relation.ispartofseries | Doctoral dissertations at the University of South-Eastern Norway;62 | |

| dc.relation.haspart | Journal Article 1: Nelabhotla, A.B.T. & Dinamarca, C.: Electrochemically mediated CO2 reduction for bio-methane production: a review. Reviews in Environmental Science and Biotechnology 17(3), (2018), 531-551. https://doi.org/10.1007/s11157-018-9470-5 | |

| dc.relation.haspart | Journal Article 2: Nelabhotla, A.B.T. & Dinamarca, C.: Optimization of electrochemical treatment of artificial wastewater using cyclic voltammetry. International Journal of Environmental Science and Development 9(8), (2018), 218-221. https://doi.org/10.18178/ijesd.2018.9.8.1104 | |

| dc.relation.haspart | Journal Article 3: Nelabhotla, A.B.T. & Dinamarca, C.: Bioelectrochemical CO2 Reduction to Methane: MES Integration in Biogas Production Processes. Applied Sciences 9(6), (2019), 1-13. https://doi.org/10.3390/app9061056 | |

| dc.relation.haspart | Journal Article 4: Nelabhotla, A.B.T., Bakke, R. & Dinamarca, C.: Performance analysis of biocathode in bioelectrochemical CO2 reduction. Catalysts 9(8), (2019). https://doi.org/10.3390/catal9080683 | |

| dc.relation.haspart | Journal Article 5: Nelabhotla, A.B.T., Khoshbakhtian, M., Chopra, N. & Dinamarca, C.: Effect of Hydraulic Retention Time on MES Operation for Biomethane Production. Manuscript submitted to Frontiers in Energy Research | |

| dc.relation.haspart | Journal Article 6: Samarakoon, G., Dinamarca, C., Nelabhotla, A.B.T., Winkler, D. & Bakke, R.: Modelling Bio-electrochemical CO2 Reduction to Methane. Proceedings of the 10th Trondheim Conference on CO2 Capture, Transport and Storage, Trondheim, June 18-19, 2019, pp. 55-61. | |

| dc.rights.uri | http://creativecommons.org/licenses/by-nc-sa/4.0/deed.en | |

| dc.subject | microbial electrosynthesis system | en_US |

| dc.subject | methane | en_US |

| dc.subject | CO2 reduction | en_US |

| dc.subject | biogas upgradation | en_US |

| dc.subject | hydraulic retention time | en_US |

| dc.title | Electrochemical Unit Integration with Biogas Production Processes | en_US |

| dc.type | Doctoral thesis | en_US |

| dc.description.version | publishedVersion | en_US |

| dc.rights.holder | © The Author, except otherwise stated | en_US |

| dc.subject.nsi | VDP::Teknologi: 500::Kjemisk teknologi: 560::Kjemisk prosessteknologi: 562 | en_US |